|

Taizhou City Huangyan Minfeng Bottle Cap Machinery Factory

|

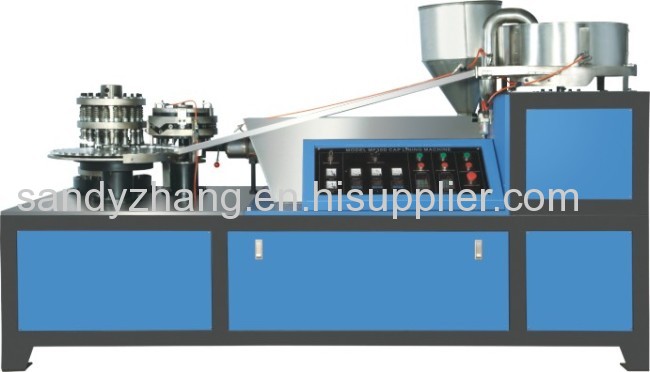

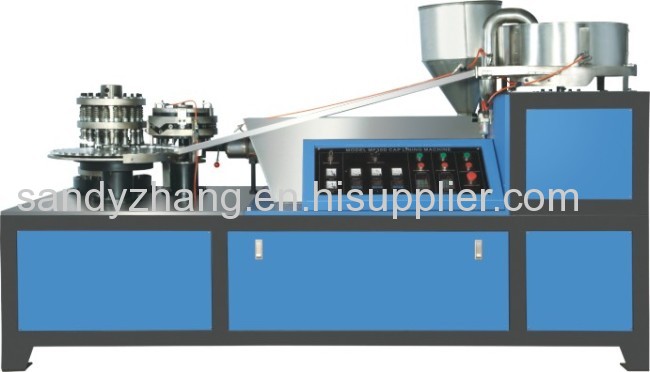

2013 New Bottle Cap Making Machinery With High Quality

| Price: | 50000.0~150000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1-Full automatic

2-Advanced equipment

3-Best in price&quality&service

4-CE certificated

Our factory is established in 1992 and our main products are compression cap molding machine,cap lining machine,cap slitting machine,cap folding machine,cap loading machine with annual output of 380 sets.Ourproduction win excellent reputation at home and abroad because of theprofessional tech,good quality and perfect service.We'd like to do ourbest to help you to be a better competitor in your market.

Advantage

Specification

Another supporting equipment you may be interested:

MF-40C Cap folding machine

MF-30D Cap lining machine

MF-30E Cap slitting machine

MF-30F Cap loading machine

This machine is particulary designed to produce bootle cap formedicine, cosmetic and beverage. It adopts advanced system of hydraulicpump and computerized automatic temperature control. There are 16 to 48cavities for your choice which depends on your productivity.

Bottle caps are made from plastic granular raw material which isfed via the hopper, fluidized with high temperature, and then forms dieblock that is extruded from the discharge outlet of the extruder, cut with the cutting tray, uniformly distributed into each die cavity and finally mould pressed.

Advantage

(1) Easy to handle, less cost and higher productivity

(2) Compared with plastic injection, the output can be increased three times

(3) Compents are easy to be assembled and disassembled

(4) Excellent in cap's quality, stable grammage and uniform wall thickness

(5) Quick mold changeover and less down time

(6) Optimized design, user-friendly touch screen control, adjustable speed of production

(2) Compared with plastic injection, the output can be increased three times

(3) Compents are easy to be assembled and disassembled

(4) Excellent in cap's quality, stable grammage and uniform wall thickness

(5) Quick mold changeover and less down time

(6) Optimized design, user-friendly touch screen control, adjustable speed of production

Specification

| 1 | Cap Diameter | 15-60 mm |

| 2 | Cap Height | 7-30 mm |

| 3 | Productivity (about 20*30mm) | 25000-27000 pcs/hr. |

| 4 | Installed Electrical Power | 60 KW (50Hz) |

| 5 | Consumed Electrical Power | 48 KW |

| 6 | Color | blue, yellow |

| 7 | Size | 3700(L)X1500(W)X2200(H) mm |

Another supporting equipment you may be interested:

MF-40C Cap folding machine

MF-30D Cap lining machine

MF-30E Cap slitting machine

MF-30F Cap loading machine

Related Search

Pet Bottle Making Machinery

New Era Cap

New Era Baseball Cap

High Quality Bearing

High Quality Oil

High Quality Belts

More>>